- Products

- View All Products

- Bridge Decking

- Industrial Tanks & Processing Equipment

- Mass Transit & Rail

- OEM & Custom Products

- Pedestrian Bridges & Boardwalks

- Standard Structural Products

- Tower Tech Cooling Towers

- Utilities & Telecommunications

- Waterfront Infrastructure

- Services

- Resources

- Why FRP

- About Us

- Blog

- Contact

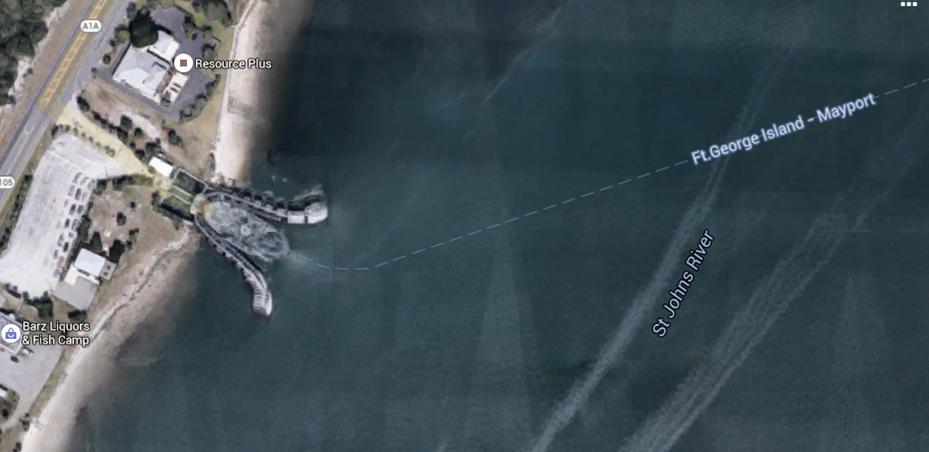

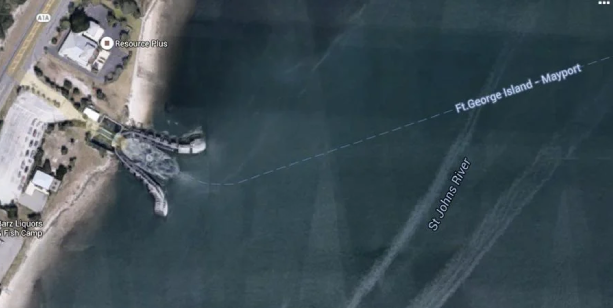

St. John’s River Ferry - Jacksonville, FL

The Jacksonville Transportation Authority needed energy-absorbing guide walls for the St. John’s River Ferry to address aggressive currents and strong winds and make berth less difficult. The JTA considered different alternatives with the primary goal to find a low maintenance fender slip wall system that would also provide greater energy absorption. Durability, flexibility, low maintenance, and corrosion resistance made FiberPile™ the material of choice.

The energy-absorbing system reduces fender wall damage and improves safety and comfort, allowing passengers to enjoy the ride. The new FRP slip walls use a combination of 24-inch and 36-inch diameter FiberPiles at lengths up to 100 feet. The wales are comprised of high strength composite timbers to distribute the impact loads to the piles. FRP channels splice the timbers along their lengths. The timbers are bolted to the piles.

LOCATION

Jacksonville, FL

PROJECT

St. John’s River Ferry

PRODUCT

Guidewalls